Strain-insensitive stretchable electronics for wearables

By Andy Tay

The development of intrinsically stretchable electronics has the potential to integrate electronic devices with human skin for applications in wearables for health diagnostics. While such a material has good mechanical robustness and offers high device density, most polymer-based, intrinsically stretchable electronics are created without strain engineering. As a result, the performance of the device and quality of the data could be affected when being used to collect physiological signals, in which there are strain variations.

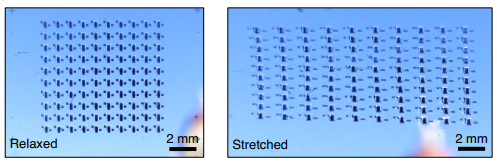

In a recent paper published in Nature Electronics, a team of researchers led by Professor Zhenan Bao in the Department of Chemical Engineering and Ph.D. student, Weichen Wang in the Department of Materials Science and Engineering at Stanford University, reported an all-elastomer, scalable fabrication process to create strain-insensitive, intrinsically stretchable transistor arrays (Figure 1). The team developed intrinsically stretchable transistor arrays with device density of 340 transistors/cm2, comparable to state-of-the-art technology, and a strain insensitivity of less than 5% performance variation when stretched up to 100% strain. The material was also used to amplify weak electrophysiological signals when used in a skin-like polymeric circuit.

“We started this work as we believe that active programming of the strain distribution crossing electronic patch can successfully suppress the attenuation of electronic performance brought by mechanical deformation, leading to stable on-skin operation of stretchable devices. It could play a valuable role in the advancement of future health monitoring devices,” says Wang.

Elastiff design offers superior mechanical and electrical performance

The team wanted to introduce patterned regions of mechanical heterogeneity called elastiff layers into their elastomer substrates. The elastiff layers needed to fulfil three criteria. First, the material should have high stretchability so that the entire device is soft and stretchable. Second, the Young’s modulus (a measure of a material’s ability to withstand change in length under extension or compression) of the material should be significantly higher than that of the substrate to minimize deformation in the active regions, such as where the transistors are in Figure 1. Third, there must be strong adhesion of the elastiff layer with the substrate. The team decided to use rigid styrene–ethylene–butylene–styrene (SEBS) material as the elastiff layer while soft SEBS as the substrate. This approach gives a modulus difference of 32 times, while ensuring strong interfacial adhesion due to similar chemical compositions.

Using simulations and experimental measurement, the authors found that even when a large global strain of 100% was applied to the transistor array in the elastiff layer, the active device only experienced ~10% strain. Importantly, their material could provide a transistor array density as high as 340 transistors/cm2 to match the best reported in other literature. There was no delamination or wrinkle formation, due to strong adhesion between the elastiff and substrate layers, which is critical for good skin conformability during bodily movements.

The team went on to characterize any impact of their material on the electrical performance of the transistor array. They found that there was no significant leakage current, negligible hysteresis, and no observable electrode-semiconductor contact issues across different strain (0% to 100%). Notably, both strain-patterned and non-strained-patterned transistor arrays have comparable charge carrier distribution and threshold voltages. Even after 1000 stretching cycles, the devices maintained their electrical performance, suggesting that the patterned strain distribution design leads to improved stability of the transistor arrays under strain.

Measuring physiological signals

The authors then adapted their material for use in a digital circuit. They created a pseudo-complementary metal oxide semiconductor (CMOS) NOR gate with six transistors and showed that the logic computation of the NOR gate was unchanged through 100% strain. The same was observed for a strain-insensitive ring oscillator with 16 transistors. Finally, they demonstrated their material in an analog circuit with stretchable amplifier for quantitative electromyography. There was excellent skin conformability, and the high level of gain also benefitted analog-to-digital signal conversion by improving data quality.

“Our all-elastomer approach for the first time achieves strain insensitive electronic performance while maintaining high device density, advanced electronic functionalities and high stretchability. For the next step, high-resolution patterning methods and new materials would be introduced for further boosting device density and performance to enable more complex applications,” Wang adds.

Strain-insensitive materials for stretchable electronics

In this paper Wang and colleagues showed that their approach to introduce an elastiff layer can improve the electrical performance of stretchable transistors. The material fabricated demonstrated high device density, high stretchability, and strain insensitivity. Their innovation makes a vital contribution to intrinsically stretchable electronics for use in wearables, such as for continuous measurement of weak electrophysiological signals for timely medical interventions.

Source article: Wang, W., Wang, S., Rastak, R., Ochiai, Y., Niu, S., Jiang, Y., Arunachala, P. K., Zheng, Y., Xu, J., Matsuhisa, N., Yan, X., Kwon, S. K., Miyakawa, M., Zhang, Z., Ning, R., Foudeh, A. M., Yun, Y., Linder, C., Tok, J. B. H., & Bao, Z. (2021). Strain-insensitive intrinsically stretchable transistors and circuits. Nature Electronics, 4(2), 143–150.

The eWEAR-TCCI awards for science writing is a project commissioned by the Wearable Electronics Initiative (eWEAR) at Stanford University and made possible by funding through eWEAR industrial affiliates program member Shanda Group and the Tianqiao and Chrissy Chen Institute (TCCI®).